APPLICATIONS – AQUACULTURE

Geosynthetic lining systems are frequently used in aquaculture projects. Typical applications are:

- Lining the intake and outlet channels where flow in an unlined channel would cause bank erosion.

- Lining of the embankment walls in the grow out ponds. The use of paddle wheel aerators causes turbulence which results in bank erosion of the ponds. Erosion is evidenced by bank undercutting and bank steepening and possible failure. Banks of ponds can be lined with HDPE or rock. HDPE has the advantage that it is smooth. Rock has the disadvantage that it presents a rough surface and can make the pond difficult to clean.

The lining of pond walls with HDPE is usually a quick job. Pond depths are usually such that 8m wide rolls of HDPE are a close fit to the bank depth, allowing for anchoring at the top and the bottom in an anchor trench with no longitudinal welding required. Generally, 1.0mm HDPE is used although 0.75mm is also common. The 1.00mm thickness has greater resistance to abrasion.

Life expectancy of HDPE can be 20 years. We have many applications which are older than 20 years and still perform adequately, showing minimum deterioration due to sun exposure.

Get Industrial Floating Covers from the Best in the Industry

Floating covers are made from high-quality and flexible geomembrane lining materials to cover tanks, ponds, and lagoons. For floating covers of different shapes and sizes, visit GDT Lining.The floating covers that we help out with are known to be applicable for multiple purposes as that of Biogas collection, Lagoons for leachate solutions and water storage reservoirs. The lining systems that awe install are known to be backed by the workmanship of dedicated experts who have the required training and experience on how things are in place.

The floating covers that we install are known to protect the water in the best possible manner. We are known to customise our covers depending on the needs of our clients and also help out with alterations whenever there is the need for it.

Being a company that has been around for several years now, we ensure that you have the right floating covers that protect the water surface well. With multiple clients as a part of our list, we assure you that you wouldn’t be disappointed with the installation that we help out with.

Benefits of using floating covers

- It controls evaporation

- Growth of Algae and organisms

- Minimisation of the emissions

- Control of odour

- It helps in deterring birds

- It prevents heat loss

While we deal with the best quality floating covers made of geo-membranes, it is something that has good longevity when compared to the rest of the products available. We conduct installation at your location while often customising the size of the floating covers well.

When you find the need for floating covers for water bodies, give us a call today, and we would offer you a good quote.

Bituminous Geosynthetic Liner is a premium product which performs well when treated with care by people who know what they are doing

A BGM is a composite material with several constituents to attain the desired overall material properties. They typically consist of non-woven geotextile and glass fleece or polyester layers impregnated with and encapsulated in elastomeric bitumen, with a sanded surface on one side for enhanced friction and an anti-root layer on the other. The geotextiles dictate the mechanical properties of the BGM, while the elastomeric bitumen provides waterproofing, chemical resistance and protection from ageing. The glass fleece is used for manufacturing purposes. It ensures stability of the geomembrane during impregnation of the geotextile with hot bitumen.

Special care is required when unloading and storing a BGL. Specially prepared laydown areas are required with special support for the rolls to prevent deformation of the material before the laying process is commenced.

Concrete Tank Lining

Concrete tanks frequently leak and deteriorate with age. Old concrete is frequently poor quality and may incorporate river gravel. Over time carbon dioxide permeates the concrete and causes the reinforcement to corrode. The corroding reinforcement expands and causes the overlying concrete cover to spall.

The concrete tank may well still have the strength to resist the hydrostatic pressure to which it is subject but leaks like a sieve. Remedial work is frequently required to the concrete structure to slow the structural deterioration. Much more work is required to restore the watertightness of the tank and slow the leaks and this later work is often fraught with difficulty. The best solution may be to carry out the repair works to slow the structural deterioration and then line he tank with an impermeable liner. The liner is usually hung from a perimeter fixing along the top edge of the tank and is made to measure to fit around the various appurtenances within the tank

If you want a structural assessment of your leaky tank give us a call. We can provide professional assessment of concrete tank lining services and talk with you about the process for fixing the problem.

Use High-quality Raw Water Pond Liners to Decorate Your Pond

Do you wish to beautify your garden and have been suggested to set up a pond? It is an ornamental one, or you intend to let fishes receive a home for themselves? No matter what your choice is, setting up a pond requires you to put in a certain amount of effort as well as an investment that would ensure that the pond is in the best condition in the years to come.

To help a pond be in its best form without encountering leakage or seepage, there is the need for raw water pond liners. Helping clients with the best pond liners for several years now, we assure you the best of the products that have good longevity.

Features of our pond liners

-

- Made to line ornamental and fish ponds

- Perfect for DIY ponds

- Made up of PVC/HDPE

- UV and rot-resistant

- Safe for fish habitat

- Multiple colours to choose from

While we understand the need to be environment-friendly, we ensure that the raw water pond liners that we provide don’t witness rotting, leakage, seepage or probably any other kind of pollution that may harm the surroundings.

Why Choose Us?

We believe in customer satisfaction, and that is the reason why we manufacture pond liners that are of the best quality. No matter how small or big you want your pond to be, we ensure that you receive the pond liner that is just perfect. You could purchase existing sizes or customise one depending on the pond size. We cater to it all while quoting competitive market prices that isn’t a pinch to your pocket.

Gdt Lining Systems have completed complex and detailed secondary containments involving the placement of lining system under and around steel storage tanks, which contain a variety of hazardous and hydrocarbon products. We have worked with jet fuel, diesel, caustic soda. The secondary containment pondage is designed to AS 1940. GDT can offer design and construct services for secondary containment systems or install only. We are more than happy to offer advice.

High Quality Pond Liners for the Perfect Pond Installation

Cleaning A pond using a high pressure nozzle. Flows of 140 litres/sec with a throw of up to 80m can be achieved with a 6” monitor hooked to an 8” pump. Nozzle pressures of 70KPa can be achieved with the right pump and delivery arrangement. Application of force of this magnitude will shake up any pond sediment deposits.

Putting the deposits into suspension is only half the story. The extraction pump system will also need to be engineered specifically for the solids and the delivery arrangement o the point of disposal.

The whole process is dramatic

Pond liners play a vital role in protecting stored water from seepages and in turn extending the pond life of water. We install high-quality pond liners for our clients. For more information related to pond liners, kindly contact us.

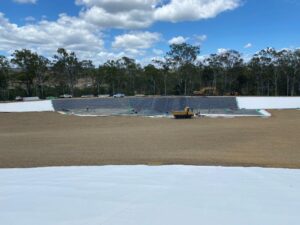

In-ground Floating Roof Water Storage

In-ground floating roof water storages are now a genuine alternative to steel water tanks when considering larger installations

Floating roof structures have advantages over steel tanks:

- Where a large volume of water is to be stored.

- Where ample land is available for the storage.

- Where it is desired to prevent exposure of the stored water to the environment and to eliminate evaporation.

- Where an off peak storage is required and it is desired to minimise pump and delivery line size and expense.

- Where it is required to construct a large capacity storage in a short period of time.

- Where it is required to use the floating roof structure as part of a lined catchment to collect rainfall.

- Where the required location of the reservoir is remote and transport of structural steel plate and members will be a high cost.

The construction costs of an inground floating roof reservoirs dramatically reduces, as the stored volume and the depth of the storage increases

The development of high strength, UV resistant, polymer materials used in the construction of floating roof storage’s has progressed rapidly in the last 10 years. A wide variety of polypropylene, elvaloy and polyethylene sheet is available with tensile strengths up to 8000kg/m width. Materials typically come with a manufacturers 20 year guarantee against UV degradation.

Click here for more information on the stages followed during an installation of a floating cover.

Geomembrane and Geosynthetic Liners for Mining Applications

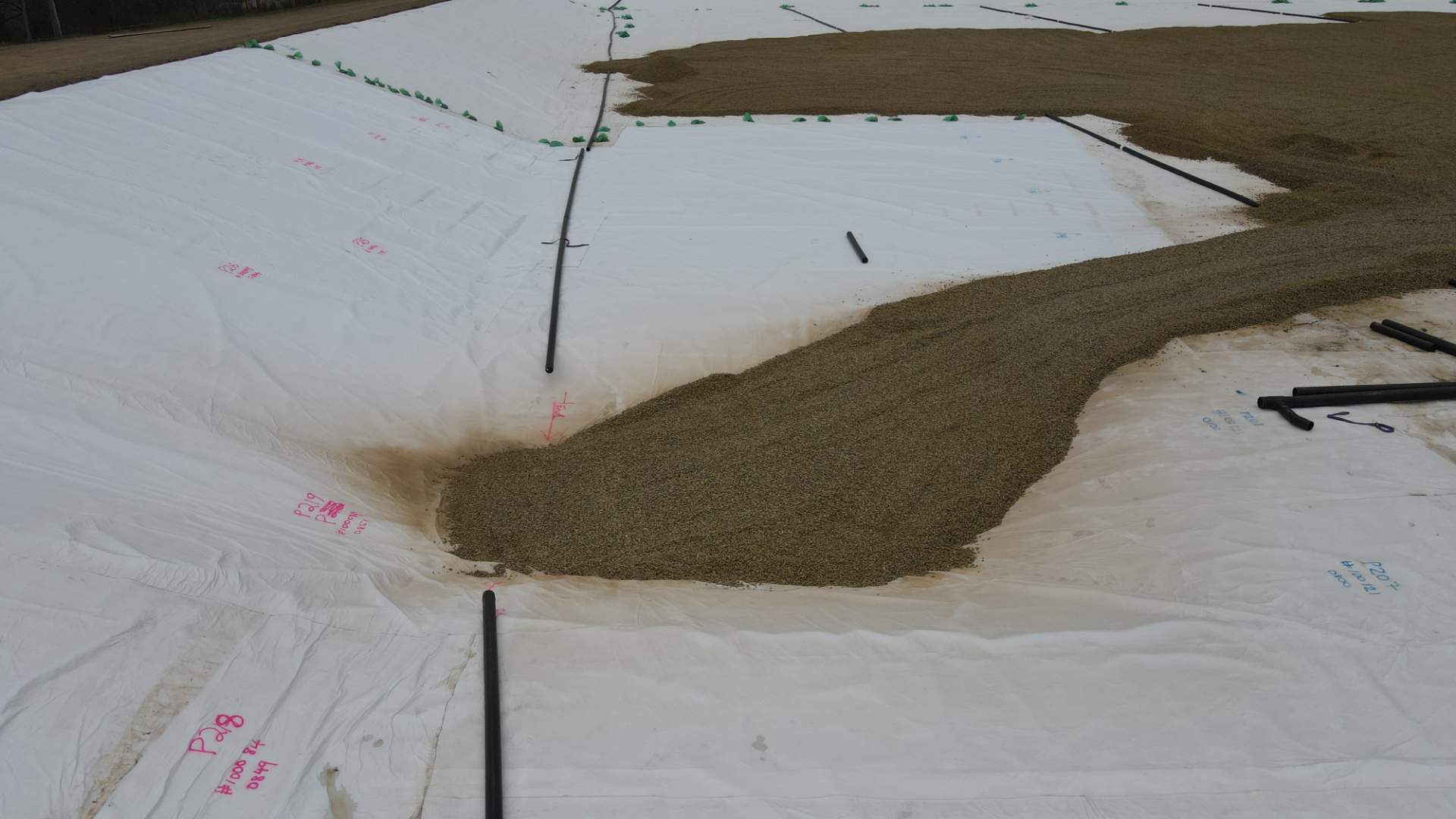

The use of geosynthetic liners in mining applications has been established science for 40 years. Specifically, HDPE has been used extensively as the lining medium for Heap Leach Pads and lining of Tailings Dams. Other geosynthetic applications have included Evaporation Ponds for the reduction of liquid waste. The complexity of the lining system for a particular application depends on the nature of the material being stored or treated.

When it comes to the need for liner systems for your industrial waste management requirements, we can be the first people to assist you. Being the leaders in providing HDPE lining, we ensure that your waste bins are lined well and that the waste is stored in a manner that is environment-friendly and safe.

With the waste bin liners in place, there is effective cleaning of the bins without having to worry about the reduced cleaning capacity. Whether you intend to choose from the ready-made HDPE lining sheets or intend to customize them depending on the varied sizes of the waste bins, we have it all for you.

The liner system that we help out with is known to line skip bins, merrels, roro’s as well as cabinet liners and a lot more. No matter what you require the liners for and how you intend to conduct waste management, we can help you with it all.

Why Choose Us?

With multiple years of expertise and experience in manufacturing liner systems and helping clients, we are known to contribute to the environment in a manner that not many can think of. With the best quality HDPE lining sheets, we help you in being the pioneers of waste management.

Being one of the leading producers of industrial waste liner systems, we believe in winning hearts of several with our wide range of accessible lining systems.

We use UV stabilisation techniques that ensure better durability and stability to the liners that we produce and help you with. Whether you want the liners to serve a short period or a for long-term assistance, you can get it for both.

Give us a call today, and we will help you with the best of quotes.

Geomembrane Liner for In-ground Molasses Storage

GDT has constructed a large number of in-ground molasses storages around Queensland in the last 15 years. The largest of which has the capacity to hold up to 37,000 tonnes of molasses. The excavation for this molasses storage is approximately 140m long, 140m wide and 11m deep. All excavation work undertaken by GDT is performed in accordance with AS3798-1990. As a result of GDT’s experience with Molasses Storages construction, they have become specialised in the requirements to make such a project successful. For an overview of this process click on the following link Molasses Storage Construction Elements.

GDT Lining Systems have recently completed the construction of a Molasses Bladder

Molasses generates CO2 and H2S when stored. Molasses often enters the storage hot and cools of emitting gas as it loses heat. If the gas is not removed from under the cover it will interfere with the roof drainage which may cause the gas flow under the cover to be blocked and large bubbles in the cover system to form. The solution is to provide:

A large central float with a gas collection pipe system on either side provides positive extraction of the gas by way of an inline industrial fan. Application of a small negative pressure under the cover has a big effect, pulling the cover down against the stored molasses and allowing water that is collected on top of the cover, from precipitation, to find its way to the perimeter drainage sump. Provide perimeter rather than central weights to the system.

GDT has been installing molasses storage for 30 years and has learned about the problems of gas produced.

GDT Lining has a mission to improve the industrial landscape by containing any harmful waste. We accept that waste is a biproduct of our industrial society. We aim to mitigate the downside to a level that is acceptable, by limiting the spread and effect of waste materials on everyday life.

Our Products and Services:

Dam Liners

Low-cost water storages

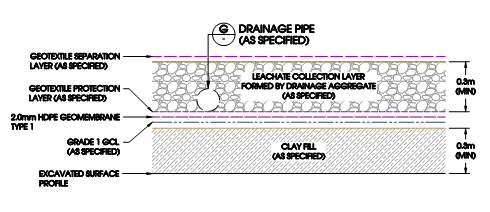

Landfill liners

Mining applications including tailings dams, leach pads and acid rock covers.

Sewerage Ponds

Contact Us

Phone: 07 40617770

Email: andrewmaddocks@geosynthetic.com.au

Web: www.gdtliningsystems.com.au